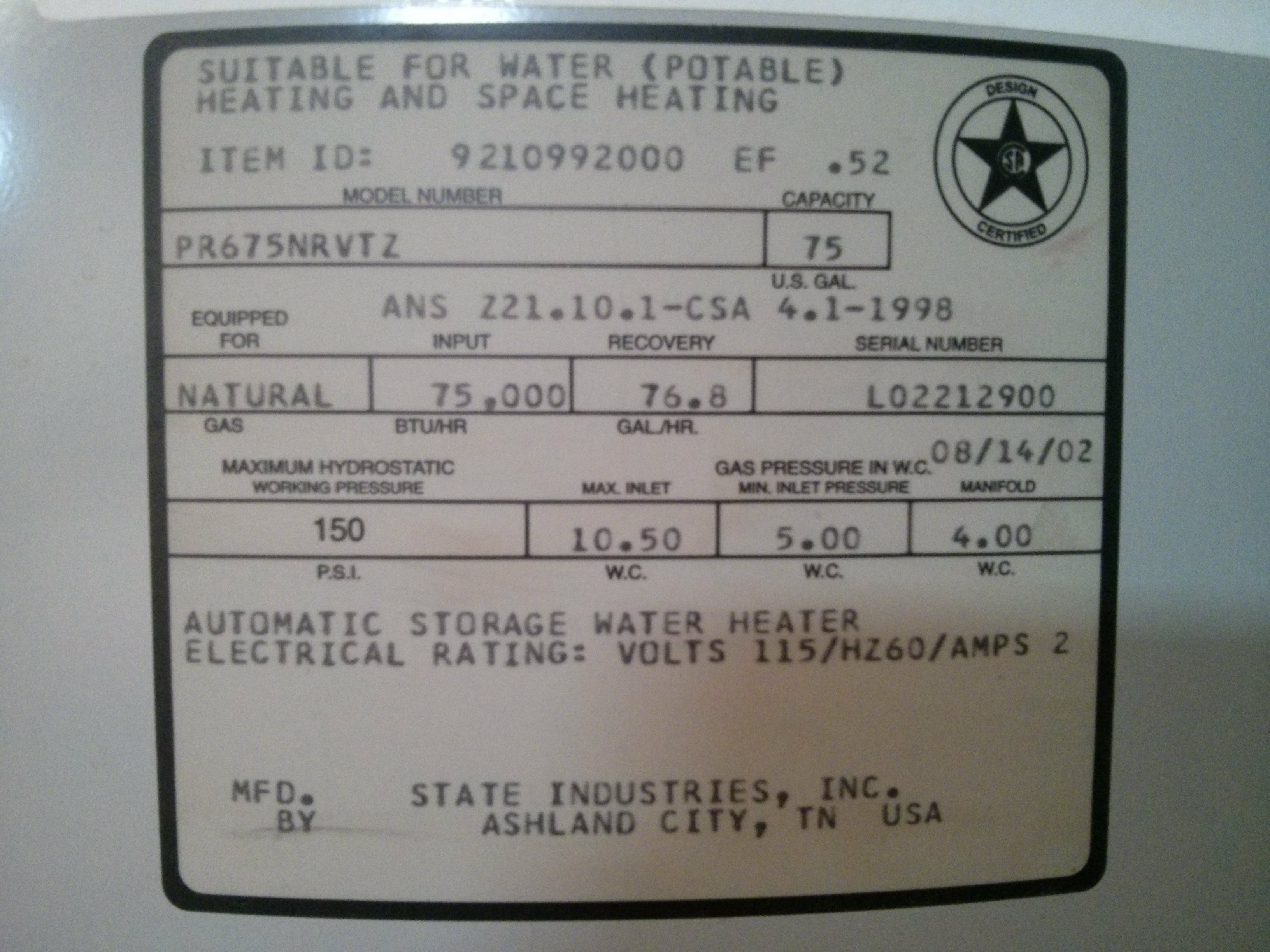

| This State brand 75 gallon capacity water heater is a "power vent" model with a 3" Schedule 40 PVC plastic flue run horizontal through an outside wall. |

| The burner is rated 75,000 BTU. |

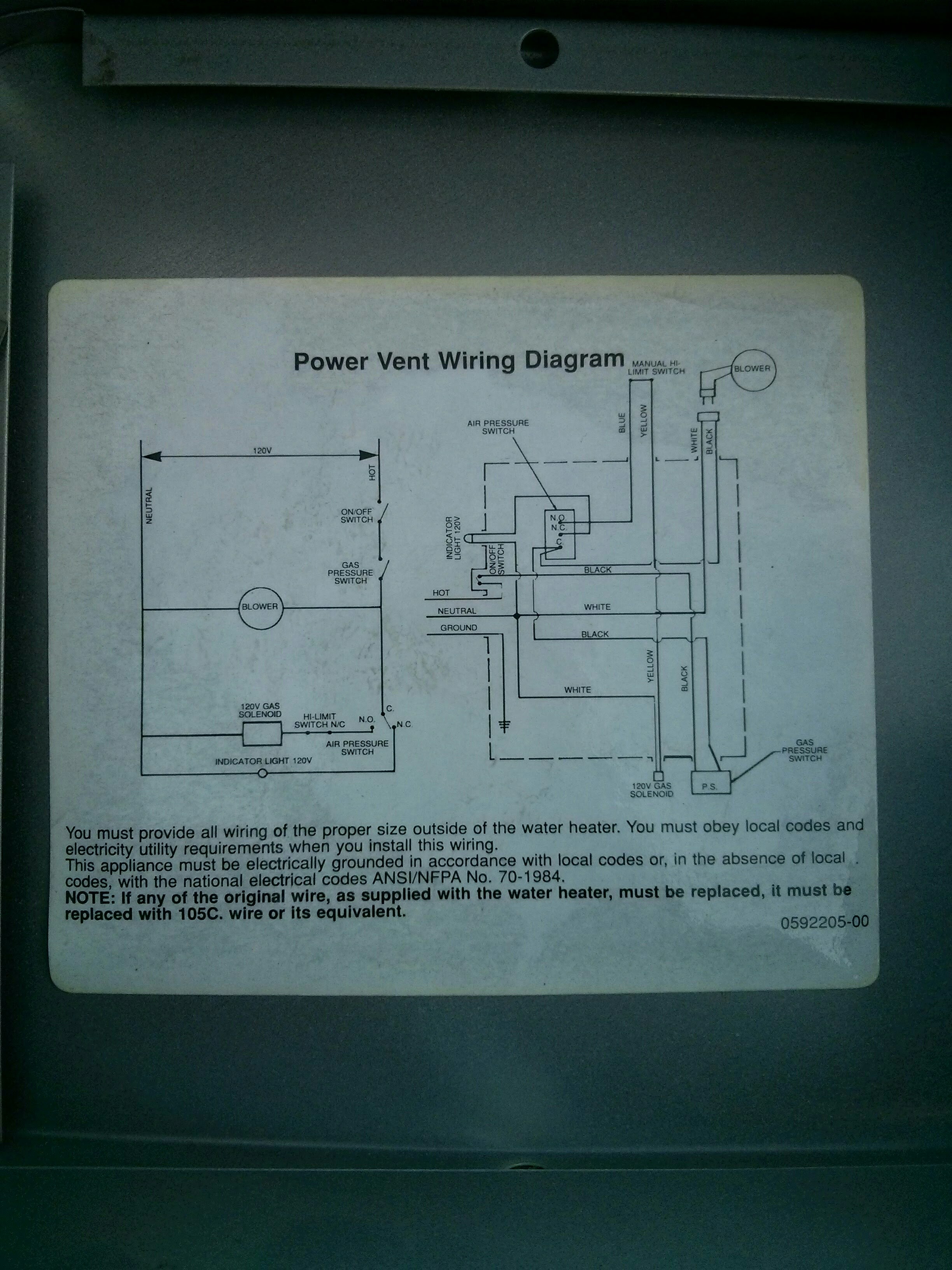

| Looking at the schematic on the left side of the image, the line voltage to the blower passes through an on/off switch and then a gas pressure switch. The induction blower motor is rated 120 Volts AC at 1.9 Amps. The line voltage also energizes a 120 V solenoid that opens a secondary gas valve. The AC induction motor and secondary gas valve solenoid are both inductive loads. Inductive loads can create a momentary arc across the contacts during switch actuations. I hypothesized that this arc sometimes caused the switch contacts to lightly weld together, preventing them from opening when the gas pressure shut off. |

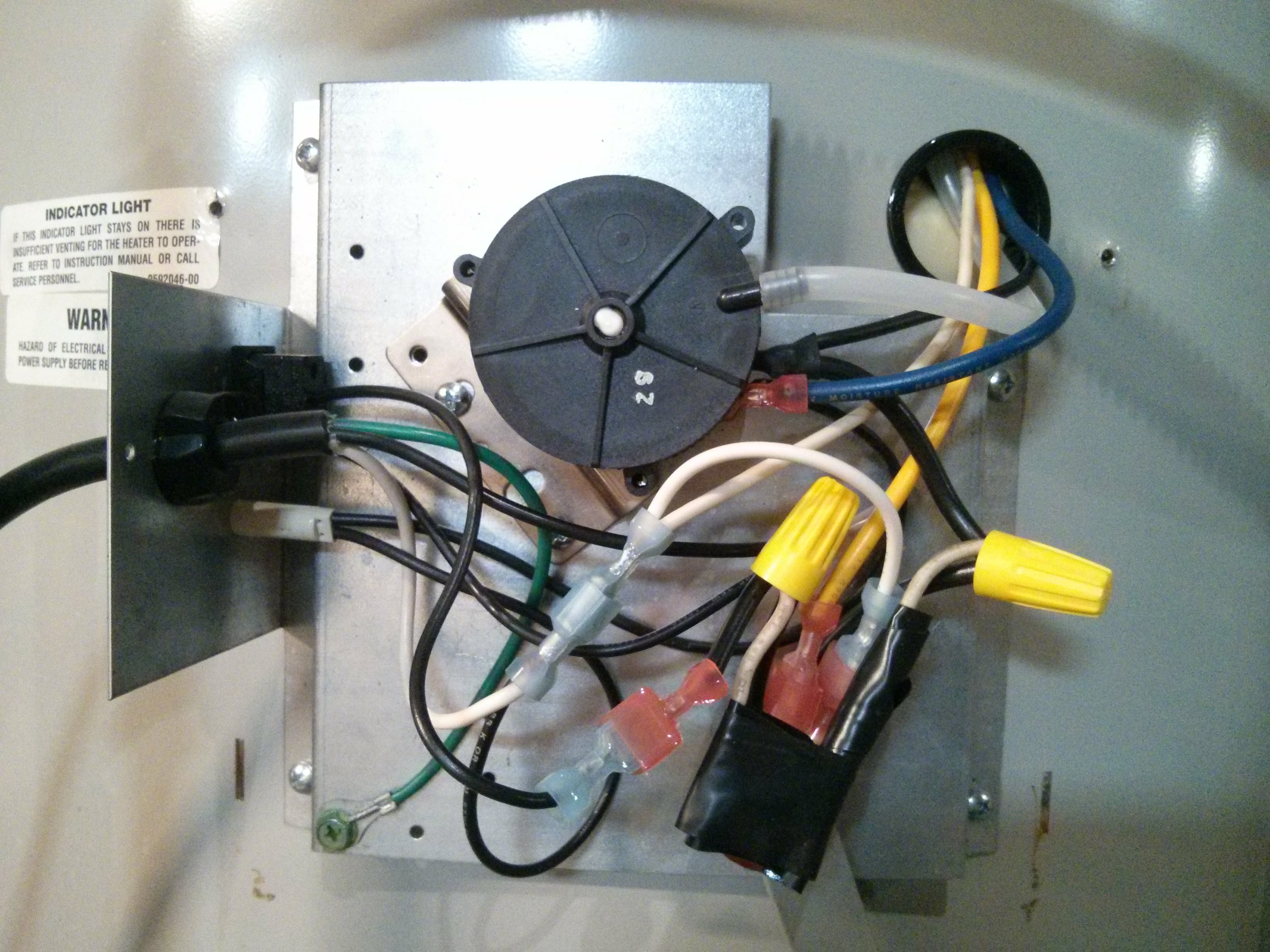

| Snubbers are commonly used to protect electromechanial and semiconductor switches against damage caused by inductive loads. I found this application note helpful in designing a suitable RC snubber circuit. I used a 0.1 uF 660 V capacitor salvaged from a failed computer power supply in series with a 150 ohm 2 W carbon composition resistor salvaged from an old vacuum tube telvision chassis. The series RC snubber circuit is wired across the gas pressure switch contacts. The snubber is the object in the bottom center of the image covered with black electrician's tape. The capacitor is on the bottom and the series resistor extends above the right side of the capacitor. |